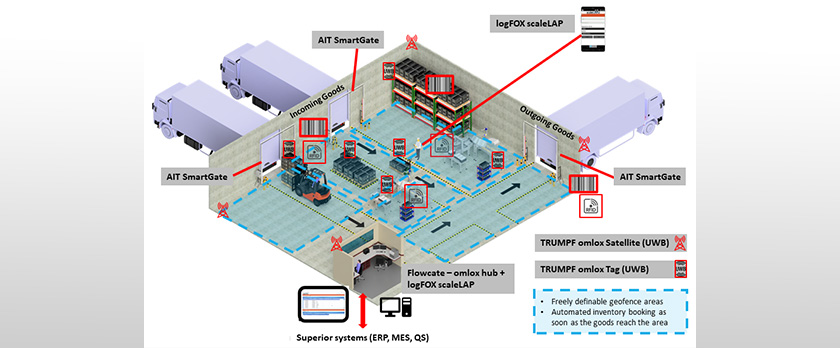

Flexible all-in-one solution with RTLS for Track & Trace in intralogistics

AIT Goehner offers a new all-in-one solution for the entire intralogistics, especially for production areas with large areas.

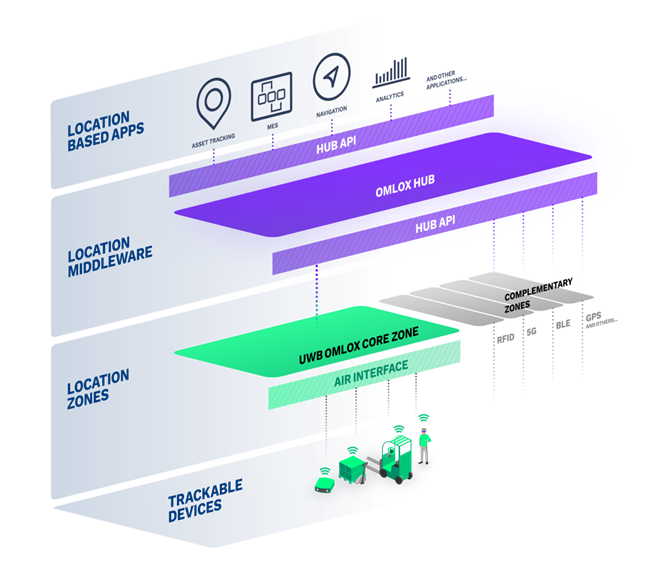

The combination of real-time locating / RTLS based on UWB (Ultra-Wideband) with identification technologies (barcode/RFID), AIT enables a cost-effective and at the same time exact, indirect location of all assets on the shop floor.

Geo-Fencing (pre-defined areas) allows for the automation of booking/scanning processes, which relieves employees and increases process and planning reliability.

The result: automation and seamless tracking of the location, condition and status of all assets on the shop floor.

- products

- goods

- part containers (e.g. pallets, mesh box pallets)

- vehicles

- tools

- equipment

between incoming and outgoing goods.