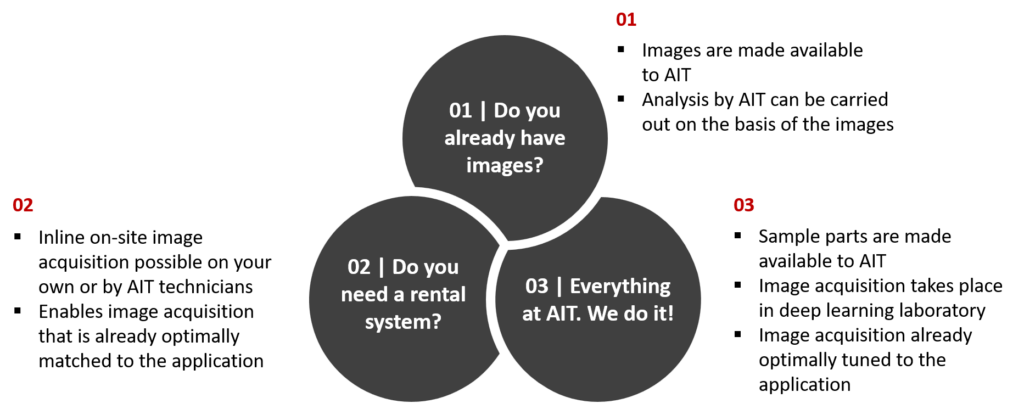

How does Deep Learning work in machine vision?

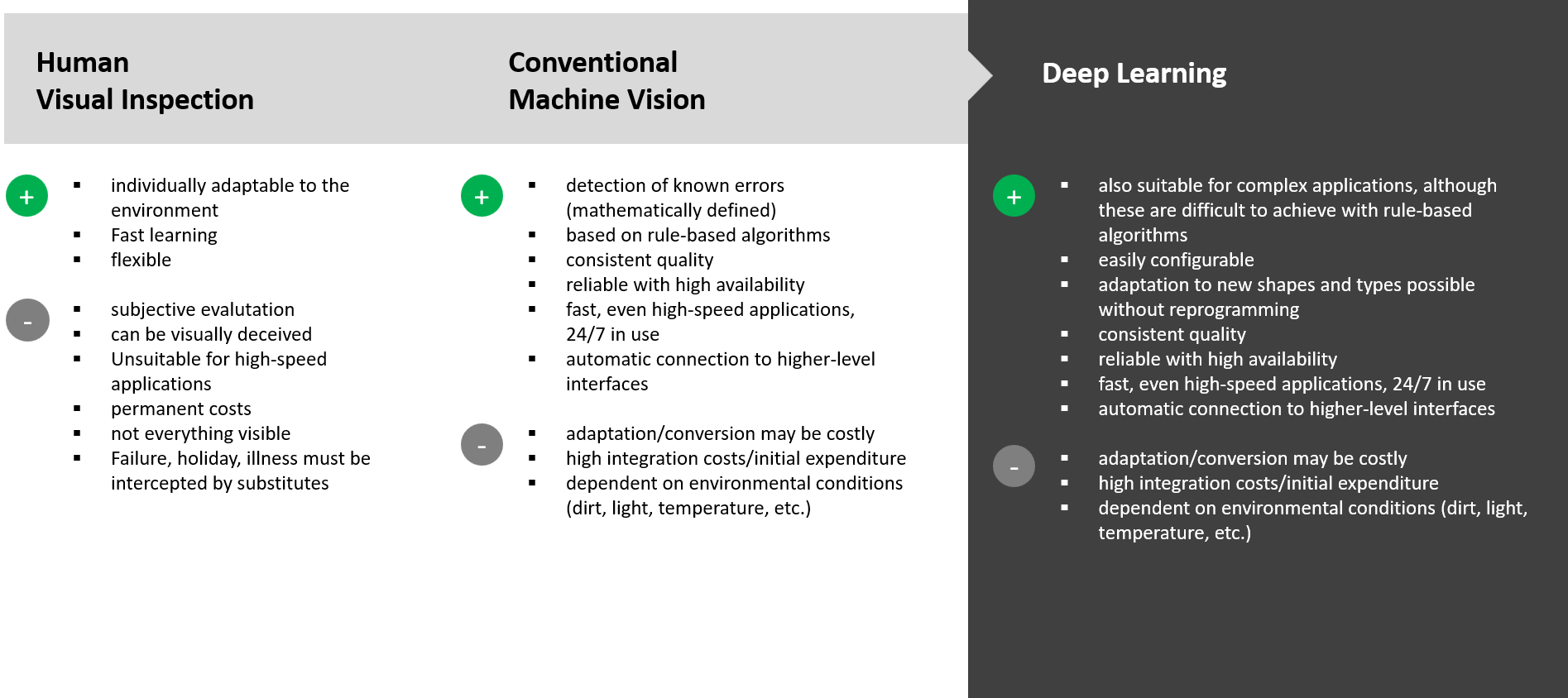

To do this, we first need to take a closer look at the known different control methods in the manufacturing process, quality inspection and traceability. A distinction is made between human visual inspections, conventional machine vision and machine vision with Deep Learning. But what exactly are the differences, the advantages and disadvantages of the individual methods?