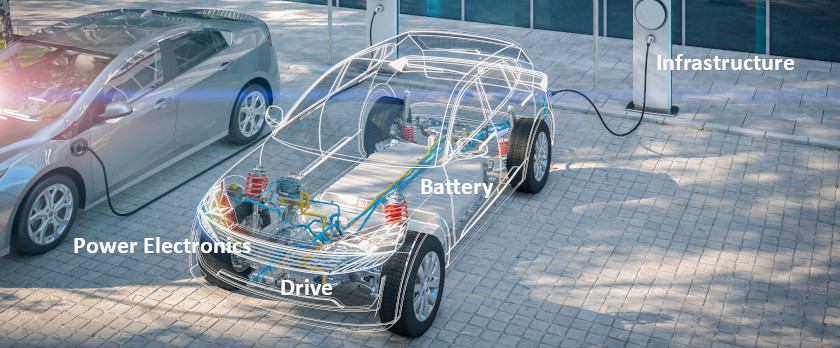

Machine Vision in E-Mobility

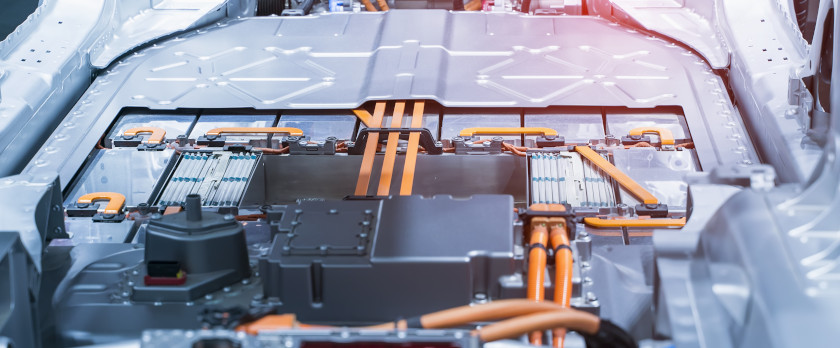

The quality requirements in battery cell production and assembly are extremely high. At AIT, we support you here, helping to make your products safer, more durable and their production more efficient.

Applications

- Production, assembly control

- Component identification including track & trace

- Detect foreign particles

- Robot guidance

- Check end-of-line control (EoL)

In particular

- Exact stacking of battery cell electrodes

» AIT determines the precise positions of the individual components for exact stacking - 2D/3D inspection also with the use of AI

» Detect blowholes and scratches in sealing surfaces

» Inspect weld seams and threads - Caterpillar inspection

» inspects sealants and adhesives as well as heat-conducting pastes for continuity and volume