Simple and reliable automation of FAST PICK STATION

The FAST PICK STATION is a unit consisting of a picking table, chute and film stretcher. It enables goods to be picked onto pallets quickly, in high quality and ergonomically.

Advantages:

- Up to 800 Picks on the pallet per hour

- Automatical cargo securement

- Shorter lead-/ and cycletimes

- Space-saving

- Flexible integration

- Ergonomic

To develop its full potential, an important automation stage is included.

ADD-ON: Automatical Packing-Layer Inspection

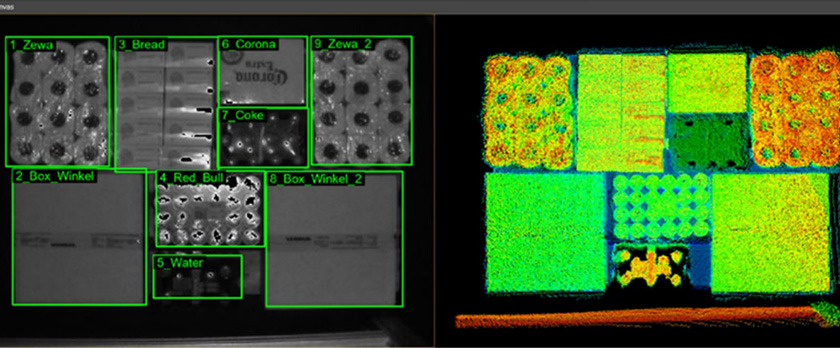

During the automatic palletizing of mixed goods by the robot cell, sporadic crashes can occur due to products falling over or deviating layer images. With the ToF SmartRunner Explorer 3-D from Pepperl+Fuchs and the software from AIT, the ACTUAL layer image is compared with the TARGET layer images every second in order to detect the shifted or incorrectly placed products and packaging.

The layer sequence and placement can also be specified in manual palletizing in order to stack ergonomically and efficiently and to check the final layer image.

- 100% layer pattern inspection ACTUAL vs. TARGET

- Early detection of deviations

- Emergency stop from a package shift of 15 mm

- Direct interface connection

- Reliable detection of layer heights up to 800 mm