Deep Learning

Deep learning elevates industrial machine vision to a new level. Instead of following rigid rules, neural networks autonomously analyze visual data and reliably detect objects, defects, and deviations even in cases of high variability. Whether under changing lighting conditions, complex backgrounds, or unpredictable faults, our AI-powered systems deliver consistent results with reduced engineering effort and exceptional scalability.

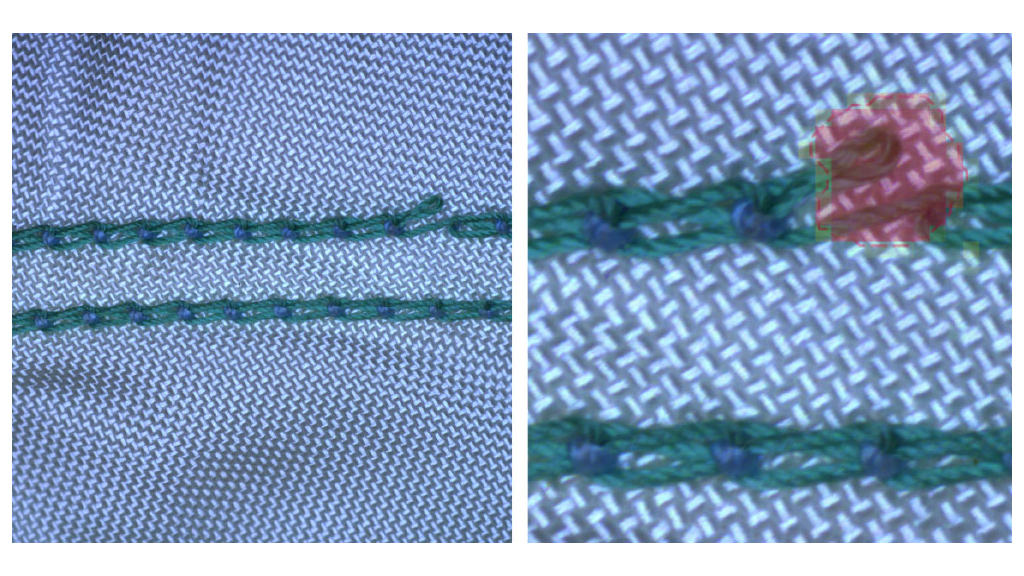

Deep learning enables defects to be quickly detected on complex parts and surfaces. To do this, a selection of good and bad images with marked defects is trained so that deviations from IO parts can be detected and, at the same time, a comprehensive understanding of the defects can be developed.

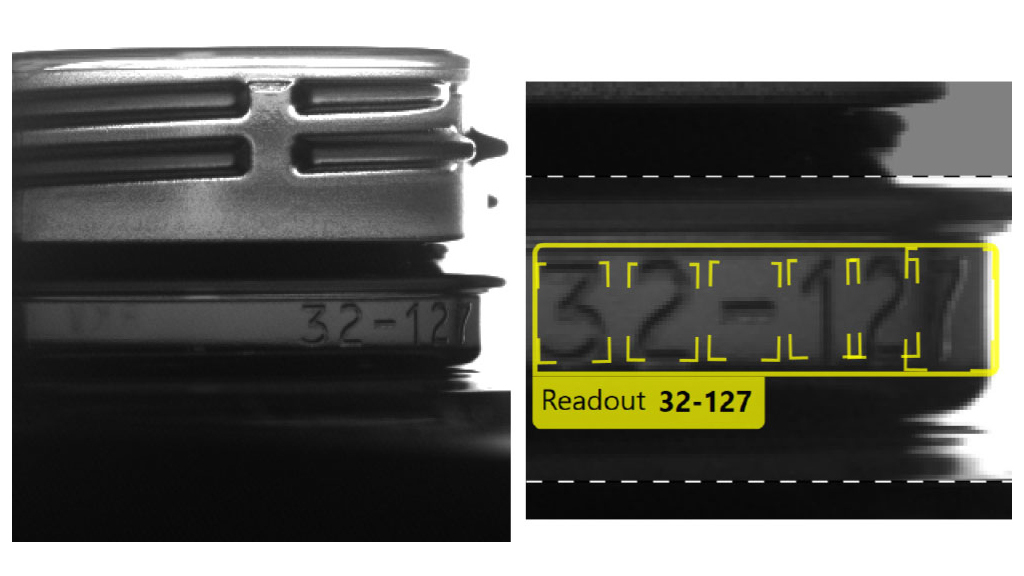

Even the most difficult OCR tasks in a manufacturing environment, such as needle-embossed codes on metal parts, embossed characters on injection-molded products, laser-engraved codes on electronic components, label-based codes on packaging, low-contrast characters, and codes on uneven backgrounds, can be solved with artificial intelligence.

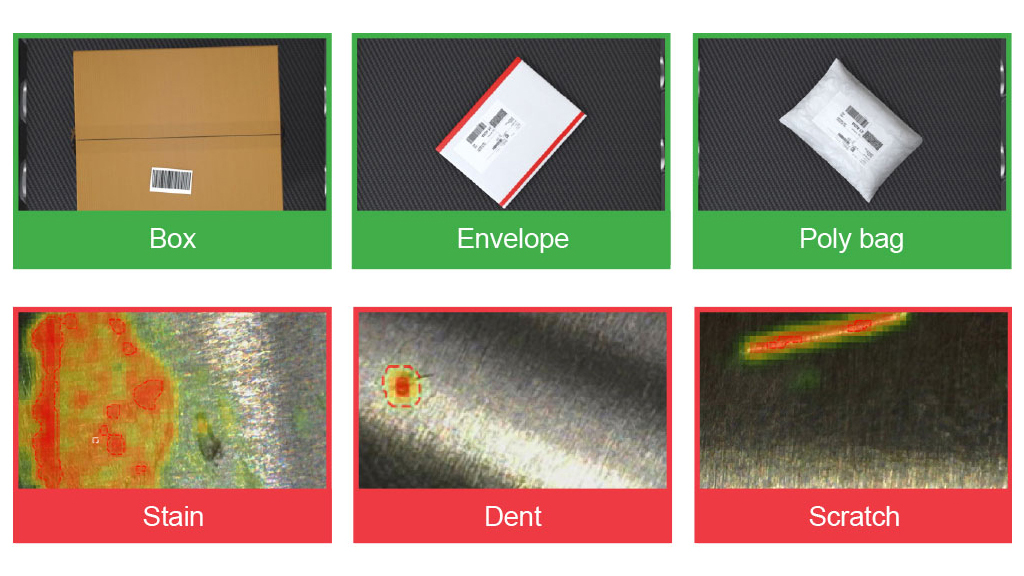

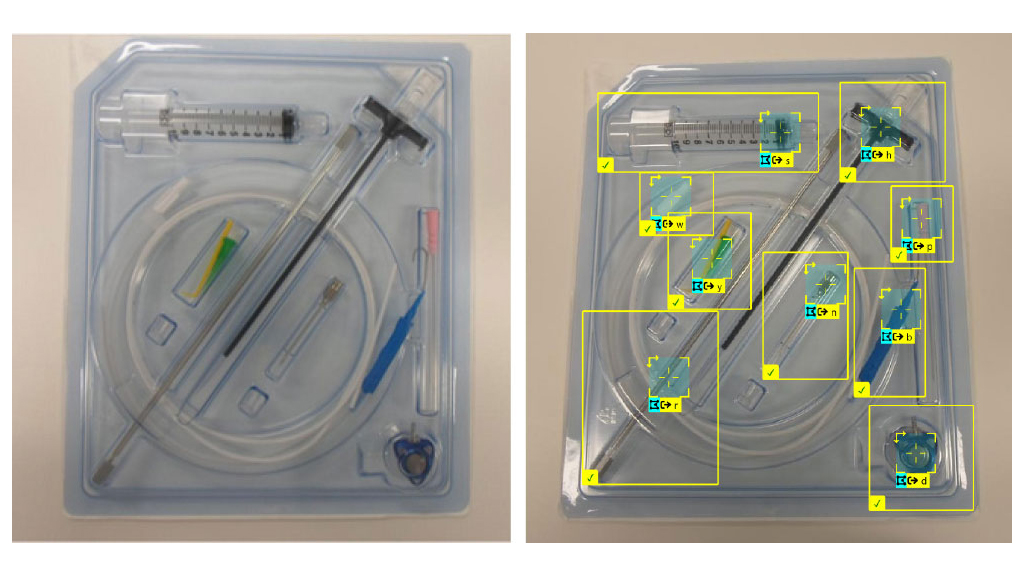

In order to distinguish between different object types in production, identify error types, and even check images, a selection of labeled images is trained. This allows products to be identified and classified into categories based on their common characteristics such as color, texture, material, packaging, and error type.

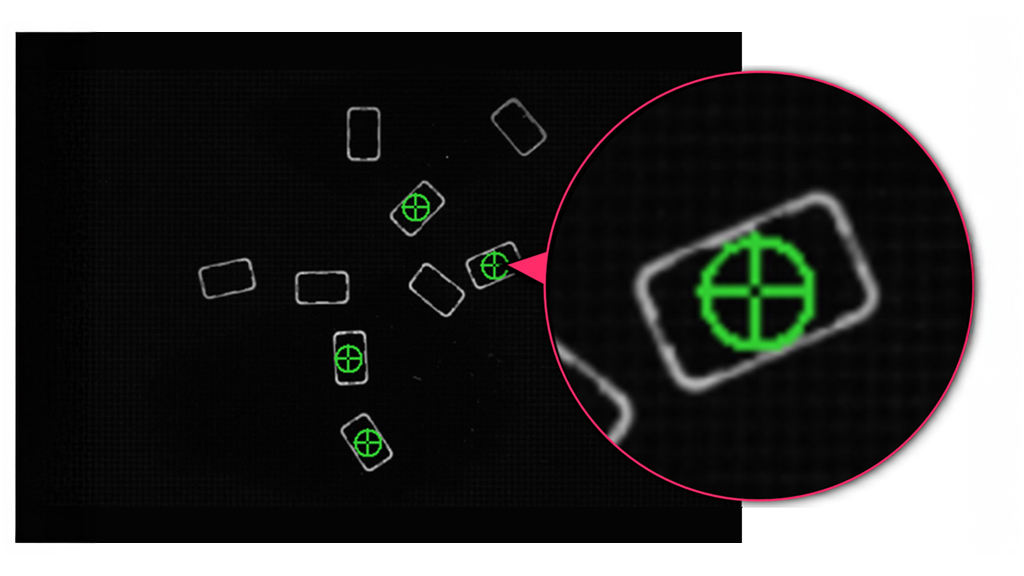

Components are randomly placed onto a vibration plate, where they are separated. The camera system must detect the parts that are oriented correctly and output their position. Because the test objects lie in irregular positions and their features are very small, rule-based machine vision reaches its limits in this scenario. With deep learning, we identify the correct orientation of the components, and classical machine vision is then used to determine the exact position so that a robot can pick them up. In this way, traditional machine vision and deep learning complement each other perfectly.

In manufacturing, complex features and objects in a field of view can be detected using special deep learning image analysis software. The software recognizes features on busy backgrounds, in poorly lit environments, on low-contrast parts, and even on parts that bend or change shape. It locates parts despite variations in perspective, orientation, brightness, gloss, and color by learning from sample images.

Deep learning step by step

AIT offers three options for project evaluation

Do you already have images?

- Images are provided to AIT

- Analysis by AIT can be carried out based on the supplied images

Do you need a rental system?

- Inline image capture on-site can be performed either independently or by an AIT technician

- This enables image acquisition already optimized for you specific application

Everything at AIT. We take care of it!

- Sample parts are provided to AIT

- Image capture is performed in the deep learning laboratory

- All images are already optimized for intended application