Identify, document, and determine volume on the fly

AIT PaketScan 3in1

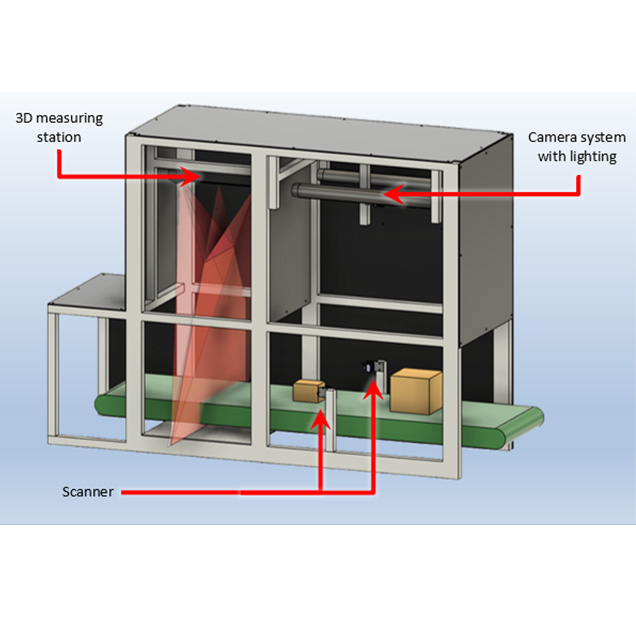

The AIT PaketScan 3in1 combines barcode identification, 3D volume scanning and photo documentation in a single continuous process. While the conveyor continues to run, the parcel barcode is read, the parcel size is checked, and the volume of the parcel contents, including the height of the box, is determined using 3D scanning. This determines whether the box can be shortened and the filling material reduced. At the same time, the contents are photographed for documentation purposes to avoid later complaints.

3 functions in one process

■ Read barcodes, check size, determine 3D volume – without stopping the belt

Reduce materials and costs

■ Shorten cardboard boxes, optimize filling material, reduce transport and logistics costs

Documentation

■ Photographic documentation of the contents creates transparency and protects against complaints.

Cycle time neutral

■ Inspection in motion, suitable for different belt widths and carton sizes

Modularly adaptable

■ Modular system – configurable for processes, bandwidths, scanners/cameras/3D sensors

Barcode + 3D volume scan + photo

Reduce boxes, optimize filling material

Transparency via photo documentation

No impact on cycle time

Modular system for your needs