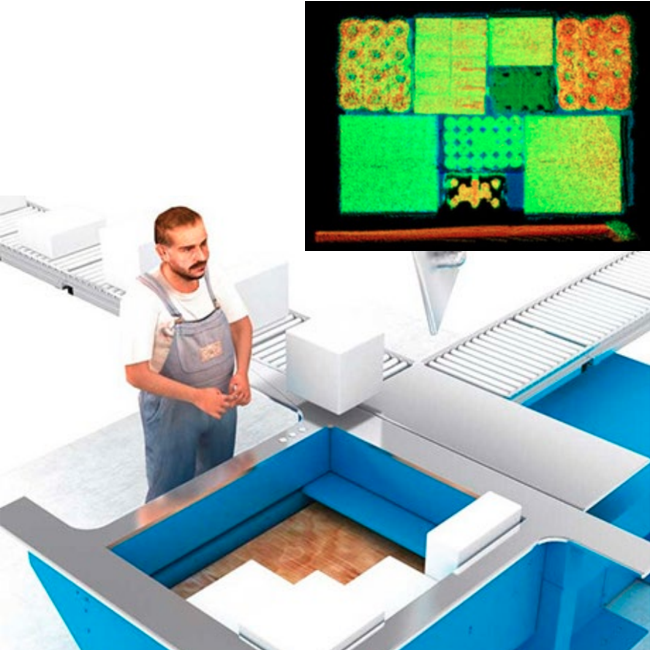

Automated packaging layer inspection for FAST PICK STATION

AIT Packaging Layer Inspection

In robot-assisted palletizing of mixed goods, sporadic crashes occur due to fallen products or deviating layer patterns. AIT Packaging Layer Inspection complements the FAST PICK STATION with an add-on that uses 3D scanning (ToF SmartRunner Explorer 3D) to check actual packaging layers against target packaging layers every second and detect incorrectly placed products in real time. This allows deviations to be detected early, emergency stops to be triggered from 15 mm package displacement, and processes to be stabilized – even in manual palletizing with a specified layer sequence.

100% actual/target comparison

■ Second-by-second comparison of packaging layers, live detection of displaced/misplaced packages

Integrated safety

■ Emergency stop from 15 mm package displacement; stable processes, fewer crashes and downtimes

Direct connection

■ Direct interface connection

Supplement automation

■ Add-on for FAST PICK STATION; manual palletizing with specified layer sequence also possible

3D ToF technology

■ SmartRunner Explorer 3D (ToF): robust 3D data for fast, reliable matching

Layer heights

■ Layer heights up to 800 mm reliably detectable

100% actual/target comparison every second

Emergency stop from 15 mm displacement

Direct interfaces

Layer heights up to bis 800 mm

Add‑on for FAST PICK STATION