AutoID

Transparency. Traceability. Quality. In modern manufacturing processes, these three factors are the key to efficiency and competitive advantage. Only those who can clearly identify their products, components, and materials at all times remain capable of acting within complex supply chains. AIT AutoID systems enable the unique identification of products, components, and packaging reliably, accurately, and in full compliance with regulations.

Quick to integrate. Versatile in application. Thanks to powerful technologies, user-friendly operation, and flexible form factors, AIT AutoID systems can be seamlessly integrated into existing production and IT environments. They support Barcode/1D, DataMatrix (DMC)/2D, and RFID technologies providing the foundation for end-to-end traceability, enhanced process reliability, and future-proof quality assurance.

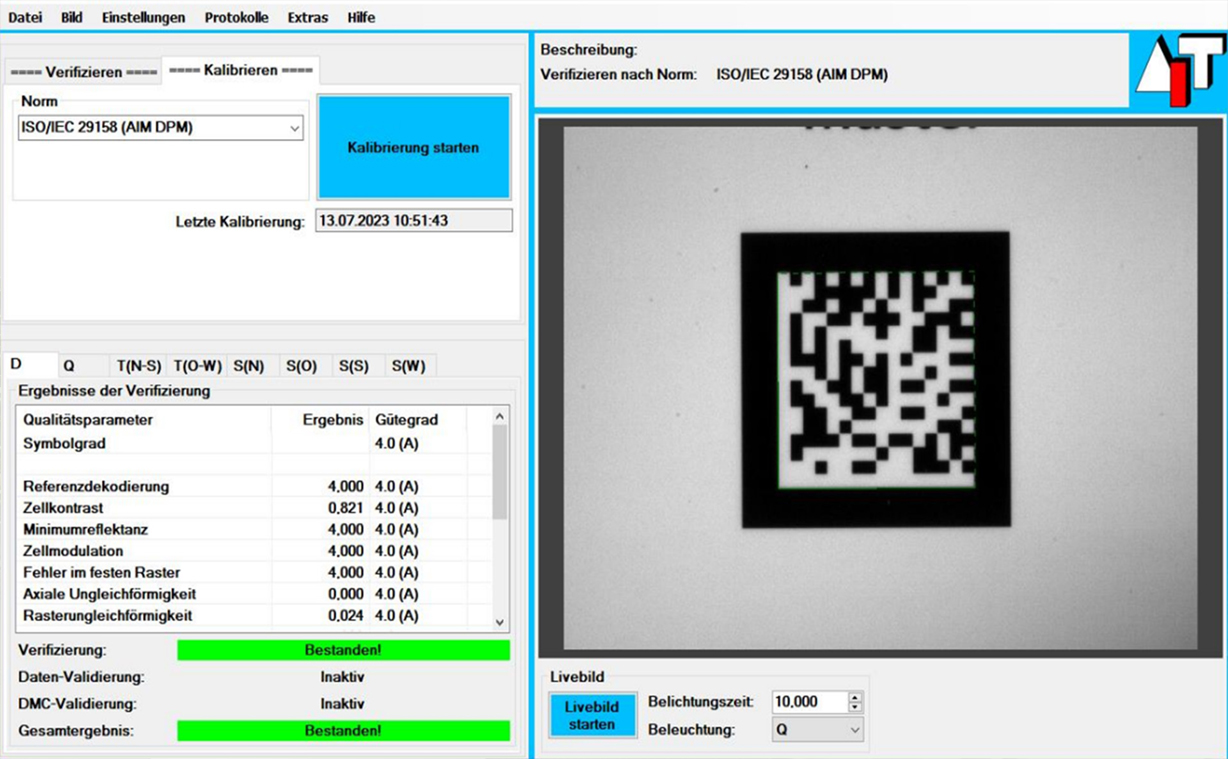

The two dimensions enable a higher density of useful information. In addition to DMCs, the camera systems can also accurately capture QR codes.

Whether needle-punched, laser-engraved, or printed codes: we test and evaluate according to all current industry standards, thus ensuring high quality and traceability.

Even at the highest line speeds or with damaged codes, our systems reliably read and process the relevant data.

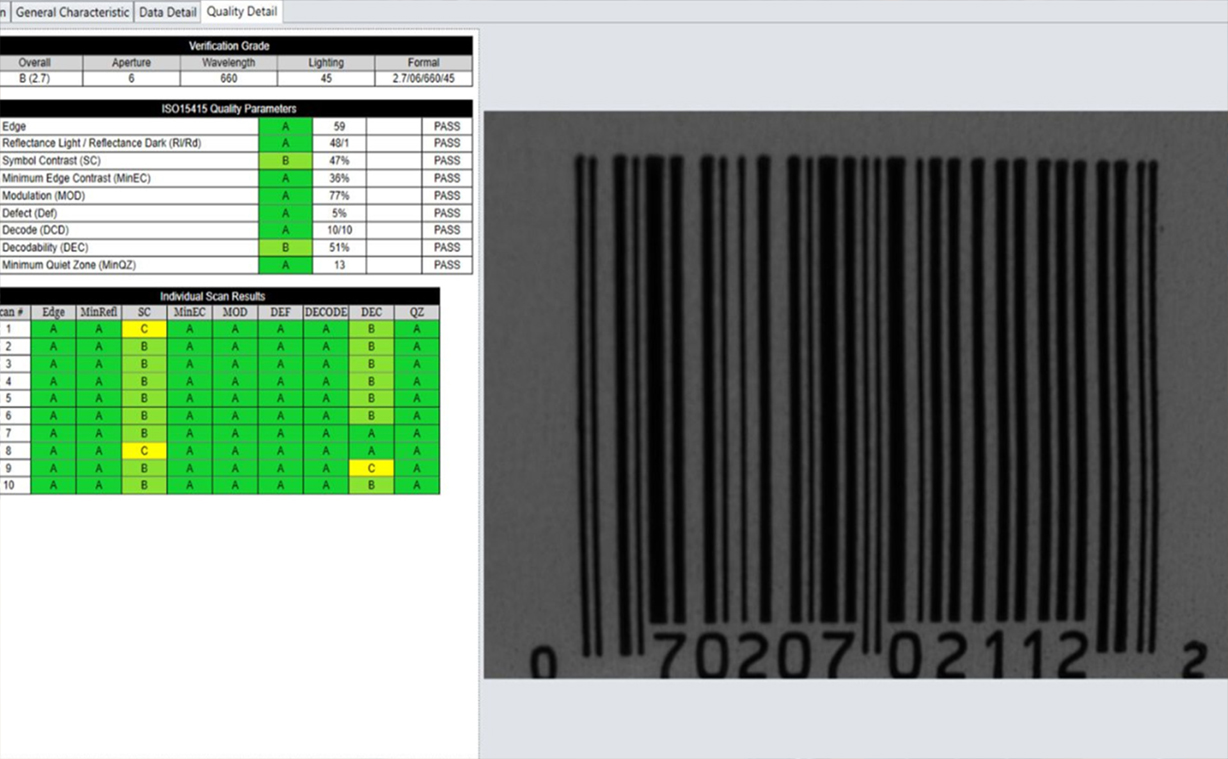

Even one-dimensional barcodes (1D codes) must meet certain quality criteria in order to be reliably read in automated processes.