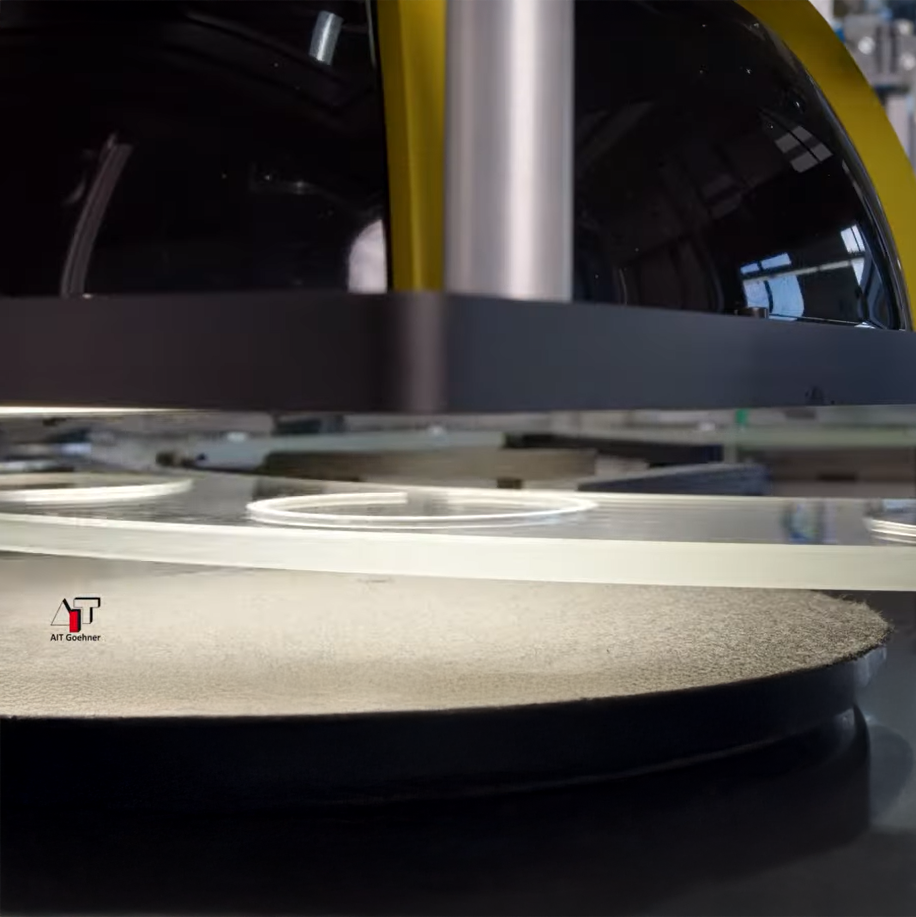

The smart solution for 100% inspection of flat components

AIT Orbit Vision System

Efficiency, precision, and reproducibility are crucial in industrial quality assurance, especially for functionally or safety-relevant components such as piston rings. With the AIT Orbit Glass Turntable Vision System, we present a powerful and economical system that has been specially developed for the fully automatic inspection of flat components on both sides.

100% inspection

■ automated 100% inspection for piston rings and other flat components

AI-supported detection

■ AI + rule-based detection, e.g., pores, cavities, scratches, rust, breakouts

trevista based

■ separation of image information into brightness and topography

Fault detection

■ Reliable and objective with minimal pseudo error rate

Flexible application

■ technically suitable for use on almost all surfaces

Universal

■ suitable for flat, stable components in all industries up to 150 mm

Economical

■ the system usually pays for itself in less than 1.5 years.

Ultimate for piston ring inspection

■ according to DIN ISO 6621 for uncoated, chrome-plated, or PVD-coated surfaces

100% inspection of flat components

AI + rule-based

trevista based

reliable and objective

Flexible and universally applicable

Ultimate for piston rings | DIN ISO 6621